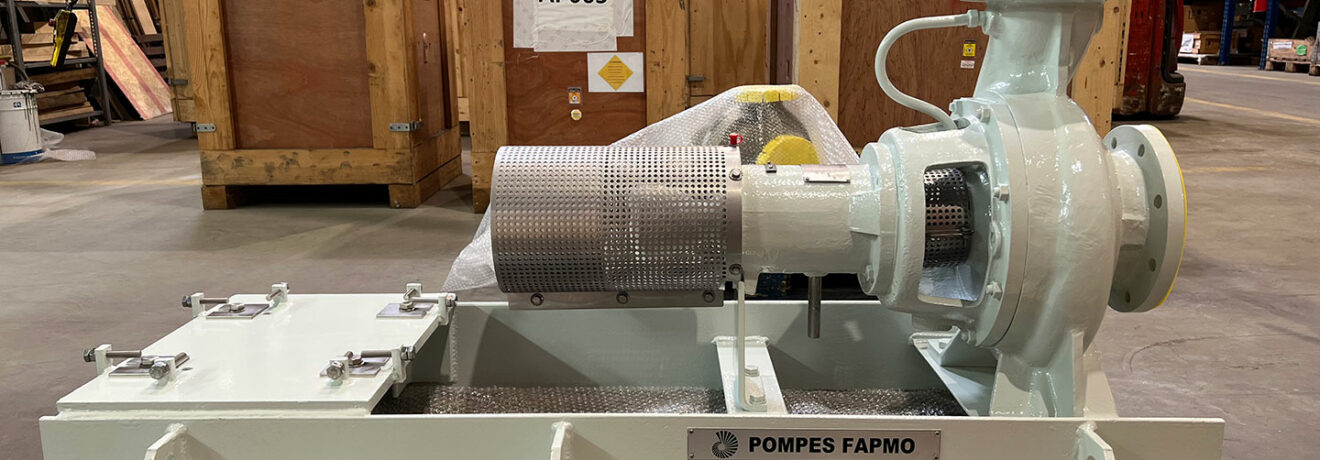

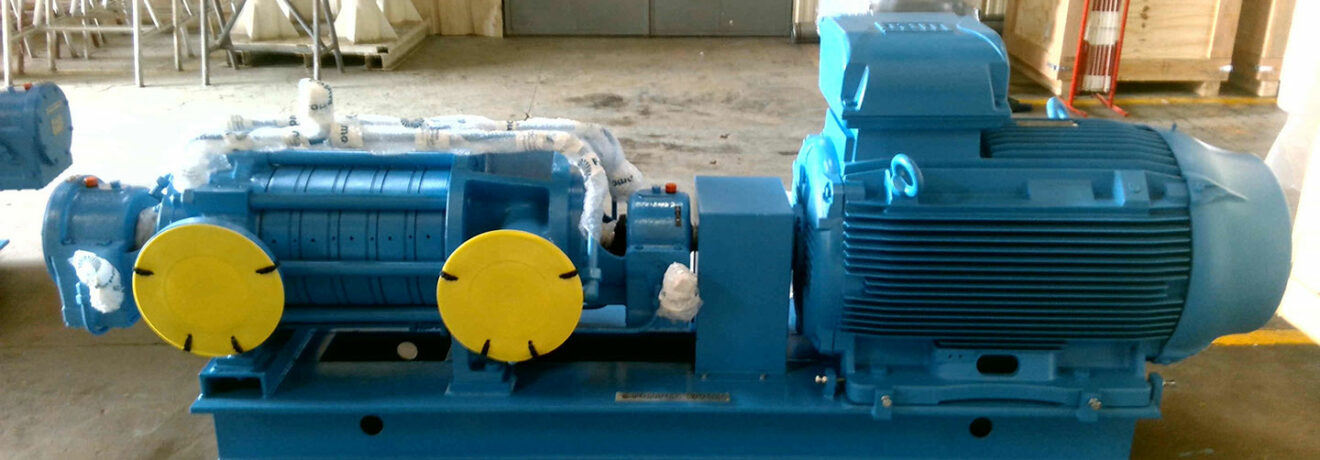

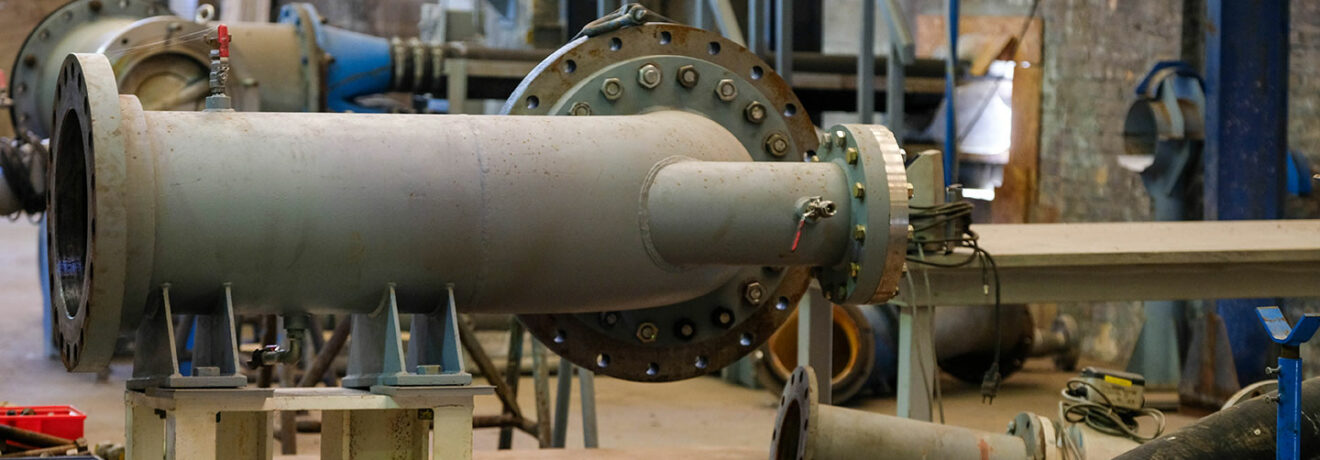

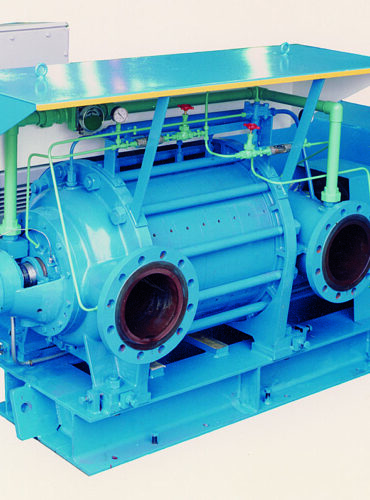

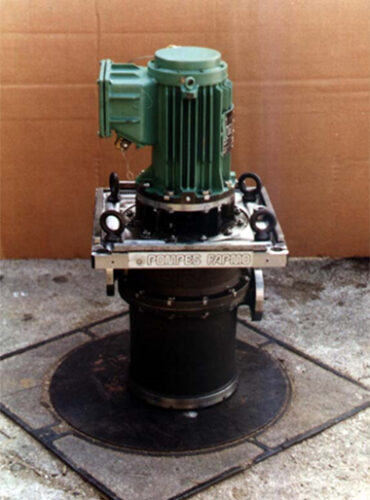

At the heart of our company lies an unwavering commitment to quality and efficiency. That’s why we’ve invested in state-of-the-art production facilities designed to meet our customers’ most stringent requirements.

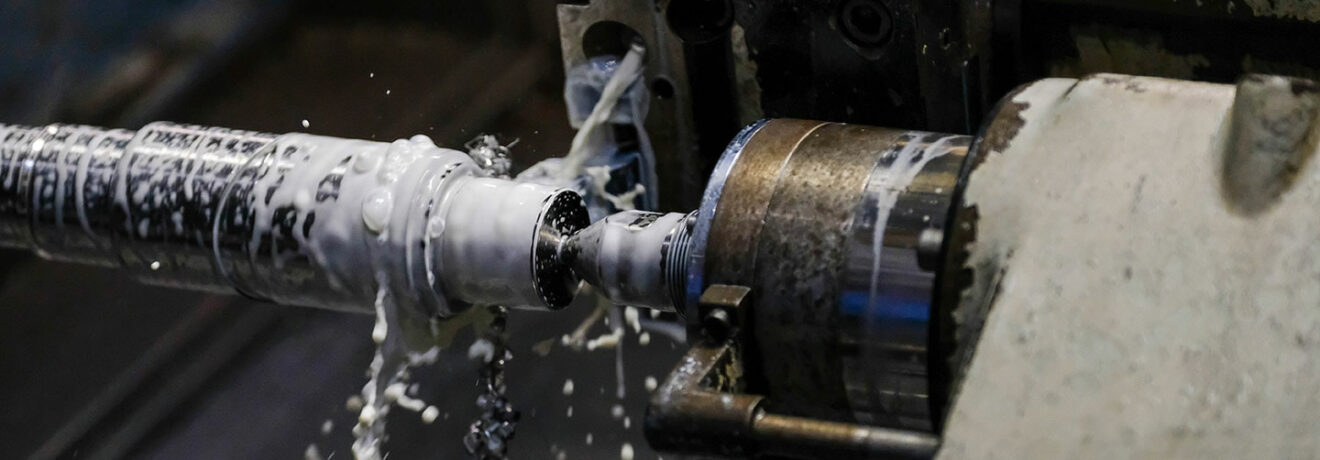

With nearly 13,000 square meters of manufacturing space, we have the space and resources to successfully complete projects of any size. Our state-of-the-art equipment includes:

- Paint booths: for a flawless and durable finish on your products.

- Test benches: to ensure the performance and reliability of every part produced.

- A state-of-the-art cleanroom: for applications requiring a controlled, particle-free environment.

Our team of qualified experts masters every step of the production process, from design to completion. We use cutting-edge technologies and rigorous methods to ensure consistent quality and on-time delivery.